Unlocking the Features of Best Open Cover Type Floor Socket with Step by Step Guide

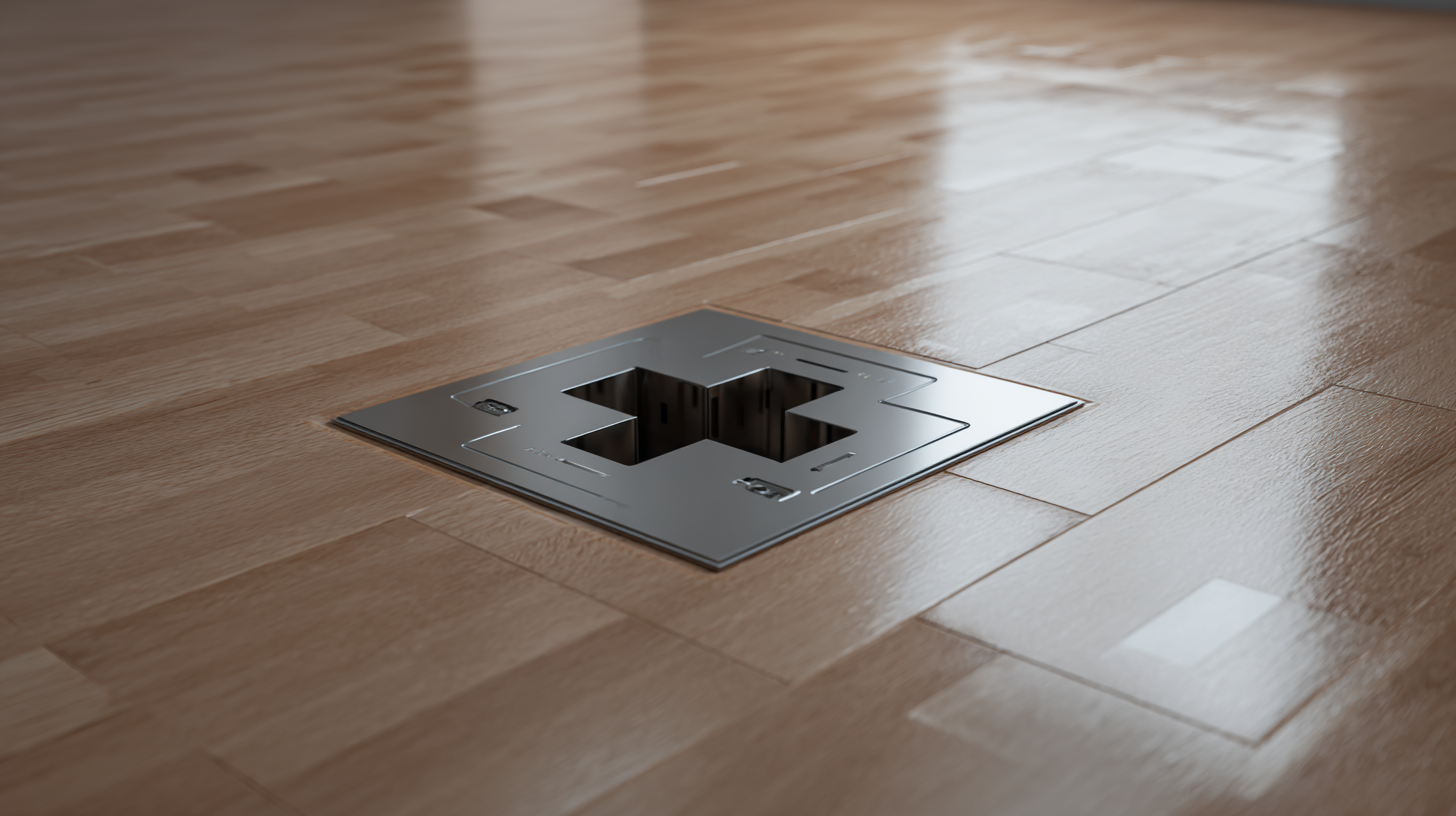

In the modern landscape of interior design and construction, the integration of functionality and aesthetics is paramount, and the Open Cover Type Floor Socket stands as a quintessential innovation in this regard. As a testament to China's manufacturing prowess, these floor sockets epitomize the balance between sleek design and practical utility, making them an indispensable feature for both residential and commercial spaces.

This blog aims to unlock the myriad features of the best Open Cover Type Floor Sockets, guiding you through the selection process with a detailed, step-by-step approach. By highlighting the unique attributes and advantages of these sockets, we will demonstrate how they can enhance the efficiency and overall ambiance of any environment. Join us as we explore the leading options available in the market today and discover why they are not just a choice, but a necessity for modern living.

Understanding Open Cover Type Floor Sockets: Key Features to Consider

When considering the installation of open cover type floor sockets, there are several key features to keep in mind. Open cover sockets are increasingly popular in modern architecture due to their versatility and aesthetic appeal. They can accommodate various plug types and are designed to minimize tripping hazards, making them ideal for both residential and commercial spaces.

One significant advantage of open cover type floor sockets is their ability to blend seamlessly into various interior designs. According to a report by the International Association of Lighting Designers, 75% of architects and designers favor products that enhance safety without compromising aesthetics. This highlights the importance of choosing floor sockets that not only function well but also complement the overall design scheme.

Tip: When selecting an open cover type floor socket, consider the load capacity. Ensure it can handle the electrical demands of your devices to prevent overheating and potential failures. Also, look for models with built-in surge protection to safeguard your electronics.

Additionally, pay attention to the materials used in these sockets. High-quality materials can significantly extend the lifespan of the fittings. As noted in recent industry reports, sockets made from robust materials can last up to 20% longer than their cheaper counterparts. Always opt for trusted brands that provide warranty options to ensure you're making a wise investment.

With the integration of a fresh ice cream shop at the Ball & Socket complex highlighting community growth, the aesthetic integration of functional elements like floor sockets becomes even more crucial in public spaces, further driving the need for thoughtful design in everyday utilities.

Step-by-Step Installation Guide for Open Cover Type Floor Sockets

When it comes to enhancing the functionality of your workspace, open cover type floor sockets are a game changer. They provide convenient access to power outlets without compromising on aesthetics. To install these versatile fixtures, follow this step-by-step guide to ensure a smooth process.

First, you need to select an appropriate location for your floor socket. Ideally, it should be in an area with high foot traffic, where you might need to plug in devices. Once you've marked the spot, carefully cut the flooring to create a secure cavity for the socket. Ensure that your measurements are precise to avoid any issues during installation. After that, place the floor box into the cavity, securing it in place, and connect the wiring as per the manufacturer’s instructions.

Next, after the wiring is done, it’s time to cover the socket. The open cover design allows easy access while keeping the socket protected when not in use. Finally, test the connections to make sure everything is functioning correctly. With careful installation, your open cover floor socket will not only look great but also provide essential power access right where you need it.

Essential Tools and Materials for Installing Floor Sockets

When installing floor sockets, having the right tools and materials is crucial for a successful and efficient setup. Essential tools include a power drill for creating holes, a level to ensure alignment, and a utility knife for cutting carpet or flooring. Additionally, a screwdriver set is necessary for fastening the socket to the floor, while a tape measure ensures accurate measurements for placement. Safety gear, such as gloves and safety goggles, should also be on hand to protect yourself during the installation process.

Materials are just as important as tools. You will need a high-quality open cover floor socket that meets your needs, along with an electrical box to house the wiring. Choose appropriate cables and connectors that comply with your local electrical codes. Sealant can be used to protect the installation from dust and moisture, prolonging the life of your floor socket. By gathering these essential tools and materials, you'll be well-prepared to unlock the features of the best open cover type floor socket, ensuring a smooth and safe installation process.

Unlocking the Features of Best Open Cover Type Floor Socket with Step by Step Guide - Essential Tools and Materials for Installing Floor Sockets

| Feature | Description | Essential Tools | Materials Needed |

|---|---|---|---|

| Open Cover Design | Allows easy access to sockets while minimizing accidental disconnection. | Screwdriver, Drill | Floor socket unit, Screws, Electrical wiring |

| Durability | Constructed to withstand heavy foot traffic and prevent wear and tear. | Wrench, Level | Reinforced housing material, Rubber seals |

| Safety Features | Equipped with protection against short circuits and overloads. | Insulation tape, Tester | Electrical connectors, Protective casing |

| Aesthetic Appeal | Designed to blend with flooring for a seamless look. | Utility knife, Measurer | Finishing trim, Color-matched flooring insert |

Maintenance Tips for Extending the Lifespan of Your Floor Socket

When it comes to maintaining the longevity of open cover type floor sockets, proper care and regular maintenance are crucial. According to the International Electrotechnical Commission (IEC), electrical sockets and connectors can deteriorate quickly due to wear and tear, especially when exposed to high foot traffic. Regularly inspecting your floor socket for any signs of damage, such as cracks or loose connections, can help identify issues before they escalate.

Keeping the socket clean is another vital step in prolonging its lifespan. Dust and debris can accumulate over time, which may lead to poor connections and malfunction. A report from the National Safety Council indicates that approximately 20% of electrical failures are attributed to dirt and corrosion. Therefore, using a soft brush or cloth to clean the socket regularly can significantly reduce the risk of operational issues.

Additionally, avoiding overloading the socket by adhering to the manufacturer’s electrical specifications will ensure safe and reliable performance, further extending the life of your floor socket.

Safety Precautions When Using Open Cover Type Floor Sockets

When using open cover type floor sockets, safety should always be a top priority. According to the National Fire Protection Association (NFPA), electrical issues are a leading cause of workplace fires, accounting for approximately 13% of all fire incidents each year. To mitigate risks, ensure that the floor socket is properly installed according to the manufacturer’s guidelines. Regular maintenance checks are crucial to identify any wear and tear that could compromise safety.

Tips for safe usage include ensuring that the socket is kept clean and free of debris, as this can prevent potential short circuits. Additionally, avoid overloading the socket; the National Electrical Code (NEC) recommends that you do not exceed 80% of the socket’s rated capacity. Always unplug devices when not in use to prevent overheating and consider using surge protectors for added safety.

Lastly, it is essential to educate all users about proper handling methods. According to a report by the Electrical Safety Foundation International (ESFI), nearly 30% of electrical injuries result from improper use of electrical outlets. Providing clear instructions and posting visible signage near open cover type floor sockets can significantly enhance safety awareness and prevent accidents.

Performance Comparison of Open Cover Type Floor Sockets

This chart illustrates the comparative performance metrics of various features found in open cover type floor sockets, focusing on safety, durability, and ease of use based on user reviews.