How to Maintain Your Kohler Generator for Optimal Performance?

Maintaining your Kohler generator is crucial for optimal performance. Regular kohler generator service can prevent unexpected failures. Imagine facing a power outage, only to discover your generator won’t start. This situation can be frustrating and inconvenient.

A well-maintained generator offers peace of mind. Checkups ensure all parts function effectively. The oil should be changed regularly, and air filters must be clean. Neglecting these tasks may lead to reduced efficiency over time.

Many users skip maintenance due to busy schedules. However, taking a few hours each year for service can save stress later. Regular maintenance helps you avoid costly repairs. Reflect on your habits, and consider if your generator is truly ready for emergencies.

Understanding the Basics of Kohler Generators and Their Components

Kohler generators are reliable, but only if maintained well. Understanding their components is essential to keep them running smoothly.

The engine, alternator, and control panel work together to provide power when needed. Each part plays a role in the generator's overall performance.

Regularly checking the oil level is crucial. Low oil can lead to engine damage. Make sure to change the oil and filter at recommended intervals. Use the right type of oil for your model. Another key component is the fuel system. Old or contaminated fuel can cause starting issues. Clear out any stagnant fuel every few months.

Tips: Keep the generator clean. Dust and debris can block airflow. Inspect the air filter often. Replace it when dirty to maintain efficiency. Also, run your generator monthly. This helps ensure all parts are functioning. If you notice strange noises or vibrations, investigate immediately. Ignoring these signs could lead to bigger problems.

Regular Maintenance Tasks for Optimal Generator Performance

Maintaining a generator ensures it runs smoothly when you need it most. One key task is checking the oil level regularly. Low oil can cause serious damage. Change the oil every 100 hours of operation or at least once a year. Use the right type of oil for your generator. This simple step can prolong its lifespan significantly.

Air filters also require attention. A clogged air filter reduces efficiency. Clean or replace it based on your usage. Remember, clean filters improve air intake. Similarly, inspect the fuel system. Stale fuel can lead to startup issues. Empty the fuel tank if your generator is not in use for a long period.

Don't overlook the battery. Check the battery connections and clean any corrosion. A good connection ensures reliable starts. Lastly, run your generator periodically. This helps prevent it from seizing up. Even with these tasks, you might overlook something. That's okay; check your generator regularly and make adjustments as needed.

Conducting Routine Inspections: What to Look For

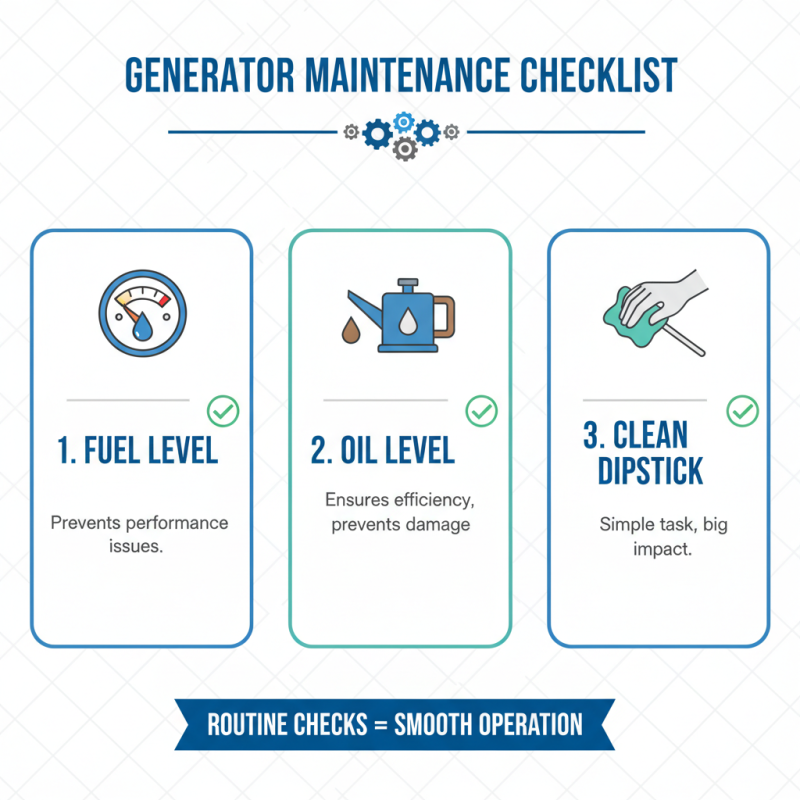

Conducting routine inspections is key to keeping your generator running smoothly. Start by checking the fuel level. Low fuel can lead to performance issues. Make it a habit to inspect the oil level too. Dirty oil can decrease efficiency and damage your machine. Use a clean cloth to wipe the dipstick. It's a small task that can make a big difference.

Next, examine the air filter. A clogged filter can choke your generator’s performance. Replace it if it appears dirty or damaged. Look at the battery as well. Ensure the connections are tight and free of corrosion. A weak battery can lead to starting problems. Pay attention to any unusual sounds during operation. They can be early signs of trouble.

Make time for these inspections regularly. It’s easy to overlook small details. Keeping a checklist can help. However, even with reminders, it’s tempting to skip these tasks. Ignoring them may lead to bigger problems down the road. Reflect on this: Are you doing enough to maintain your equipment? Regular checks ensure reliability when you need it most.

Replacing Oil and Filters: Guidelines for Kohler Generators

When maintaining your generator, oil and filters play a crucial role. Regularly replacing oil ensures the engine runs smoothly and effectively. Dirty oil can lead to mechanical issues. A simple task is checking the oil level monthly. Always use the recommended oil type for best results.

Changing oil filters is equally important. A clogged filter can restrict oil flow. This could cause parts to wear out quickly. When changing the filter, remember to clean the area around it. Expect some mess. It's part of the process.

Tips: Always use gloves when handling oil and filters. This helps avoid skin irritation. Dispose of old oil responsibly. Regular maintenance saves money in the long run. Set a reminder monthly to check your oil and filter. This small step can prevent bigger problems later. Keep an eye on performance changes too. They often signal when a change is needed.

Oil and Filter Maintenance Schedule for Generators

This chart illustrates the recommended maintenance frequency for oil and filter changes in generators over different time periods. Regular maintenance is crucial for optimal performance and longevity of your generator.

Troubleshooting Common Issues to Ensure Smooth Operation

When dealing with generator maintenance, troubleshooting is crucial for smooth operation. Issues like irregular performance or failure to start can be frustrating. According to industry reports, up to 20% of generator failures result from inadequate maintenance.

Regularly inspect the fuel system. Clogged fuel filters or stale fuel can hinder performance. Even minor fuel leaks can lead to significant issues. Check the oil level frequently. Poor lubrication can cause engine wear. The American Society of Mechanical Engineers states that proper oil maintenance can extend the lifespan of the generator by 50%.

Electrical connections are another common area of concern. Loose or corroded terminals can disrupt power flow. Engineers recommend checking these connections every few months. Additionally, keeping the generator clean can prevent overheating—a frequent issue for neglected units. Dust and debris build-up can affect cooling efficiency. Remember, if problems persist, consult a professional. Some issues reveal deeper mechanical faults that require expert intervention.

Related Posts

-

Maximize Your Home's Power Security: Essential Kohler Generator Service Tips You Need to Know

-

Why Regular Kohler Generator Service is Essential for Reliable Power Supply

-

Essential Tips for Choosing the Right Power Generator Service for Your Home Needs

-

Why Power Systems Generators Are Essential for Reliable Energy Supply

-

How to Choose the Best Home Backup Generators for Your Needs?

-

2026 Top Power Station Innovations and Trends to Watch Out For?